Bi’dry is a garage-type anaerobic digestion solution designed for dry batch digestion. It's tailored to process organic wastes with high dry matter content (over 25%). Bi’dry is a modular, efficient system resistant to contaminants, dedicated to biogas production from solid residues.

Renewable way

Waste treated by our solution:

Livestock waste

Livestock waste

Municipal solid waste

Municipal solid waste

Green waste

Green waste

Organic industrial waste

Organic industrial waste

The process

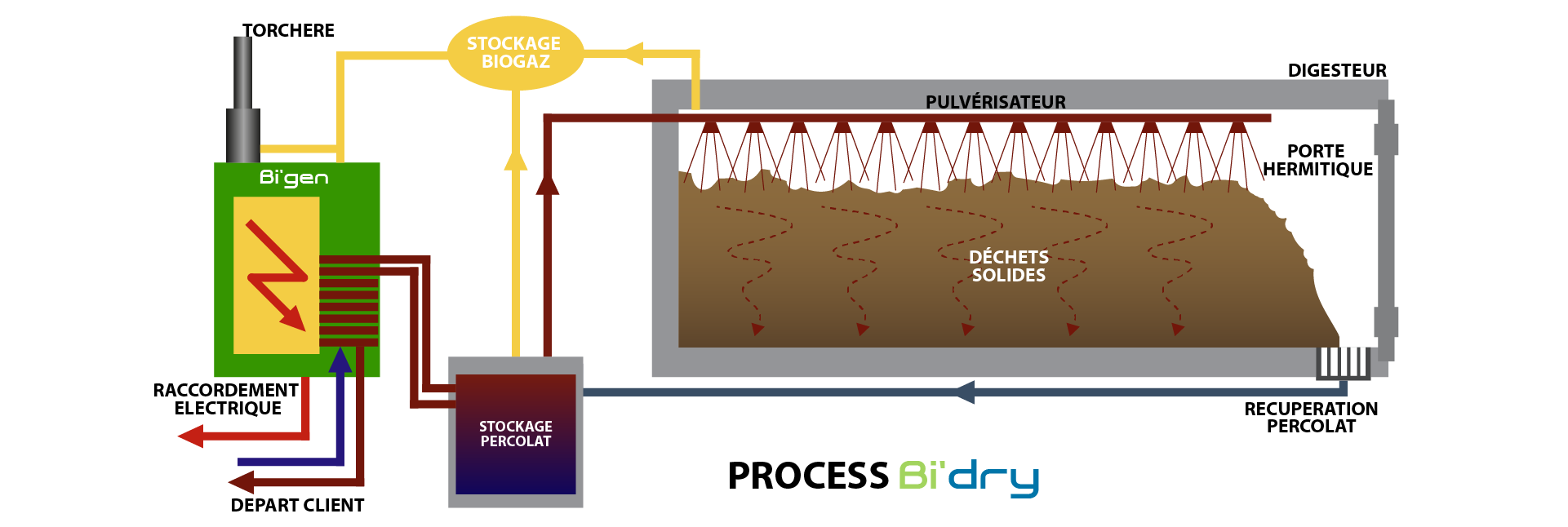

Working principle:

The principle behind the Bi’dry solution involves operating multiple digesters simultaneously in parallel, typically ranging from 4 to 8 digesters.

The feedstock is loaded into the digester and the digestate is unloaded manually in a cyclic fashion using a wheel loader. Following this, the material undergoes fermentation for a period of 4 to 6 weeks at temperatures corresponding to either mesophilic or thermophilic digestion regimes (42°C and 55°C). Percolate recirculation irrigates substrates to ensure the necessary bacterial input, heating, and agitation throughout the cycle to activate digestion. Throughout the digestion process, the produced biogas is gradually treated and stored in the gas holder. This gas will then be utilized in a CHP unit, to generate both electrical and thermal energy.

| Solution | Quantity of waste (tons/year) | Electric power (kWe) |

|---|---|---|

| Bi'dry 18 | 1000 - 1500 | 18 |

| Bi'dry 34 | 1500 - 1800 | 34 |

| Bi'dry 50 | 1800 - 3500 | 50 |

| Bi'dry 75 | 3500 - 5000 | 75 |