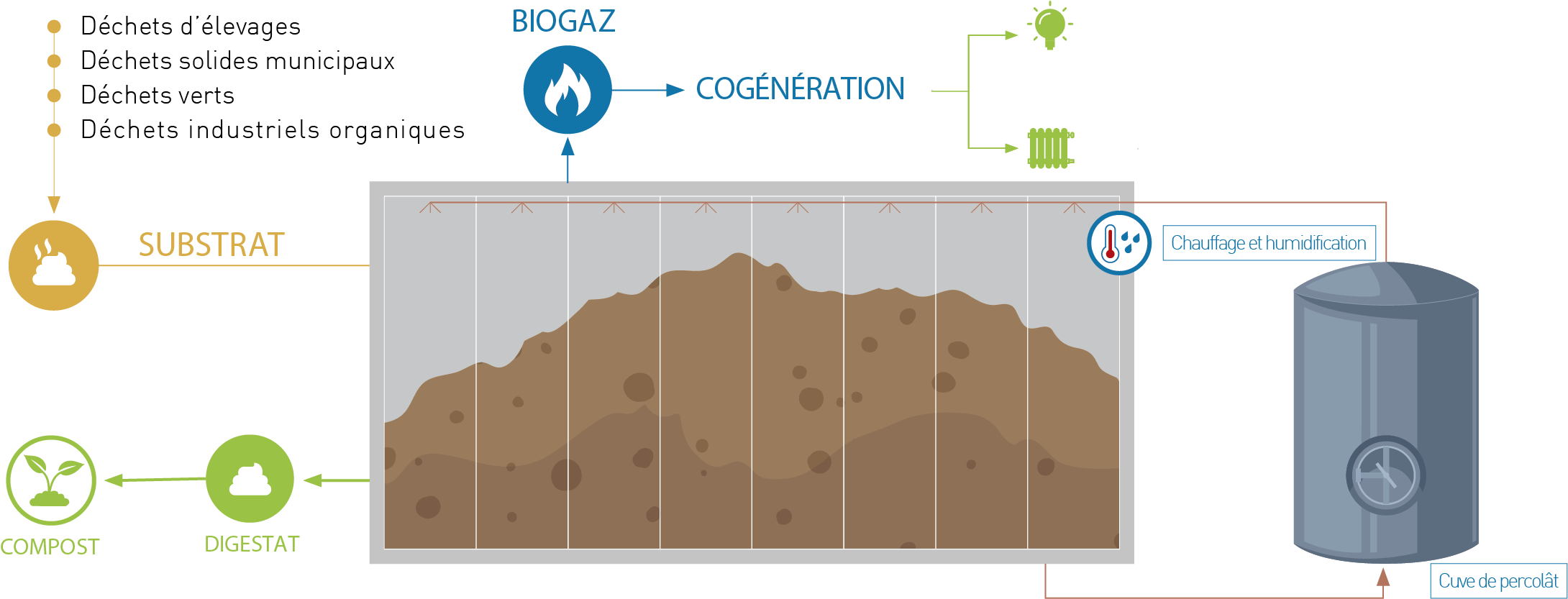

Bi’dry is an innovative, proven system designed for the anaerobic digestion of solid organic waste with a high dry matter content. > 25%. This modular and compact system is perfectly suited to the recovery of stackable waste, guaranteeing optimal biogas production while effectively resisting contaminants.

La solution Bi’Dry repose sur l’exploitation simultanée de plusieurs digesteurs en parallèle. Le chargement des intrants et le déchargement du digestat s’effectuent de manière cyclique à l'aide d’une chargeuse sur pneus. La fermentation de la matière se déroule sur une période de 4 à 6 semaines, à une température correspondant au régime de digestion mésophile ou thermophile (42°C ou 55°C).

The substrates are watered by a recirculation of percolate allowing the multiplication of the necessary bacteria, heating and agitation throughout the cycle to activate digestion. During the methanization cycle, the biogas produced is gradually treated, then stored in the gas holder. This biogas is then sent to the cogenerator designed from a MAN® engine block to produce both electrical and thermal energy.

Livestock waste

Agricultural waste

Municipal waste

Industrial waste

Livestock waste

Livestock waste

Green waste

Green waste

Municipal solid waste

Municipal solid waste

Organic industrial waste